Converting Flare Gas Into Bitcoin

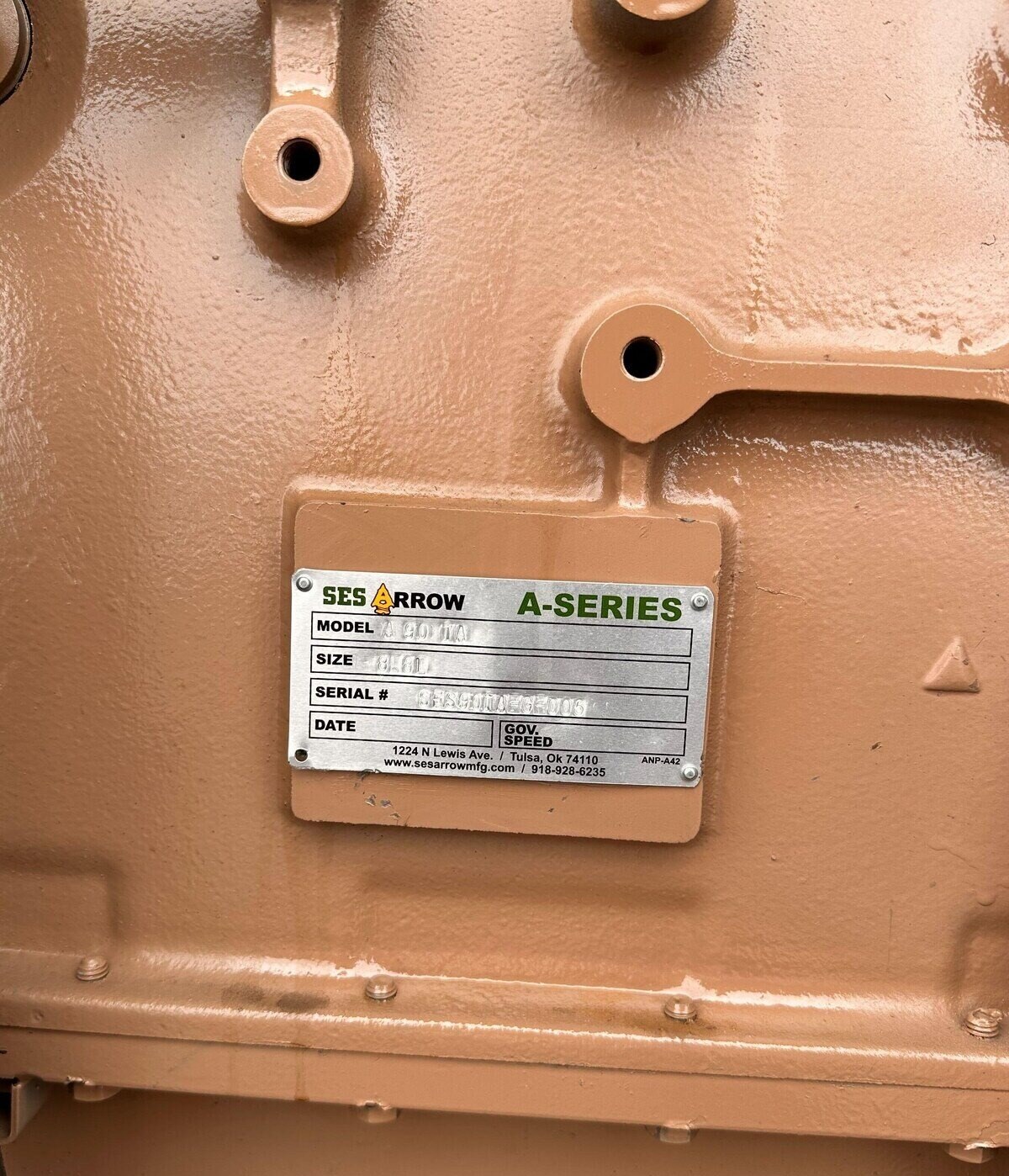

Partnering with SES Arrow, this project tests their 90kw engines on smaller, more distributed sites to expand the reach of our Wasted Gas Solution.

Services Provided

- Site Feasibility Study

- Project & Vendor Management

- Training Local Pumper

- Deployment & Commissioning of Miners

- 24/7 Live Monitoring

- Ongoing Data Center Operations

- Financial Reporting

Data Center Details

- Size: 180 kW

- Cooling: Air Cooled

- Power: Off-Grid Natural Gas Powered

- Miners: S19j Pros

- Digital Currencies: BTC

Partners

- SES Arrow

- ACS

- PA Ventures

Project Time

- 2025- Ongoing. Adding a 3rd generator before EOY.

About The Project

Site Selection

Our team performed site feasibility analysis and partnered with the O&G producer to identify this smaller flare site in the North Texas county of Hardeman which had a good gas composition including no H2S. The low flow rate allowed us to pilot small deployments that are perfect for some producers that want to start slow and profitably mitigate small volumes of gas.

Flare Gas Mitigation & HB 591 Tax

Gas at this site was previously being flared, wasting valuable natural resources and sending harmful methane emissions into the air. With our Wasted Gas Solution, this previously flared gas was piped into an SES 90kW generator to transform gas into power. Additionally, the financial model for this project factors in Texas House Bill 591 (HB591) which provides an exemption on the severance tax for this gas which would have otherwise been flared. Learn more about this flare gas mitigation bill and how we're leveraging this tax strategy on this project.

Smaller Engine Testing

We have a vision to roll out our Wasted Gas Solution at distributed sites across the United States which have less gas flowing and require smaller engines. We partnered with SES Arrow on this project to place 2 of their 90kW natural gas engines at site to consume roughly 50 Mcf/day to power a mobile data center running bitcoin miners. Proving out these smaller engines are critical to offering O&G operators a tested solution to deploy our solution at smaller sites including orphaned wells, allowing them to waste less and earn more.

Standardized SOPs

At smaller distributed wells, a key component to keeping Opex costs low is to leverage the pumpers who are already visiting these sites regularly. On this project, we created SOPs and trained the on-site O&G operator to perform routine daily maintenance tasks like ensuring the generator is running properly, checking fluid levels, and tending to minor maintenance on the bitcoin servers. These SOPs are delivered through an easy-to-use mobile app that tracks work performed and provides a history used to predict larger maintenance tasks in the future.

Reduced Ongoing Opex Costs

An ideal site location, combined with right-sized natural gas engines and SOPs that allow existing operators to handle routine maintenance keeps ongoing Opex costs very low meaning O&G producers can roll out this Wasted Gas Solution at wells all over the US with flow rates as little as 30 Mcf/day.

This project proves out that our solutions really do mitigate flaring and reduce methane emissions, keep opex low, and allow operators to waste less and earn more.

The Impact

This pilot project has successfully proven we can mitigate flared gas through smaller right-sized SES engines and leverage existing operators with no previous data center technician experience to handle routine daily maintenance. With low monthly Opex and a ~2 year Capex payback period, our Wasted Gas Solution is a proven way for O&G operators to waste less and earn more.

“It's been really easy to use the SOPs and mobile app the DC team has provided. My crew can check off daily maintenance tasks and log in the app in about 5 minutes and if I need any help, the DC team is a phone call away.” - Site Operator

The Impact

This pilot project has successfully proven we can mitigate flared gas through smaller right-sized SES engines and leverage existing operators with no previous data center technician experience to handle routine daily maintenance. With low monthly Opex and a ~2 year Capex payback period, our Wasted Gas Solution is a proven way for O&G operators with wasted gas as low as 30 Mcf/d to waste less and earn more.

.png?width=335&height=403&name=hashhut-front-on-upstream-logo%20(1).png)

-1-1.jpeg?width=1756&height=2000&name=quanah-aerial-view%20(1)-1-1.jpeg)